Micro deep drawing is a forming technique where metal sheet is deformed under mechanical pressure into a seamless three-dimensional shape.

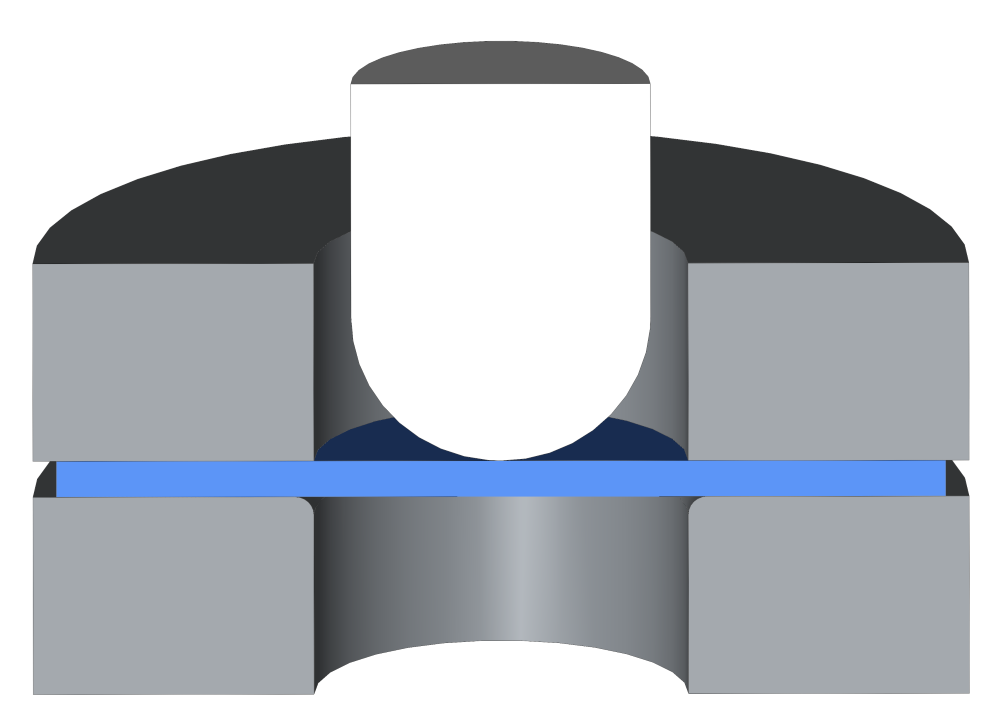

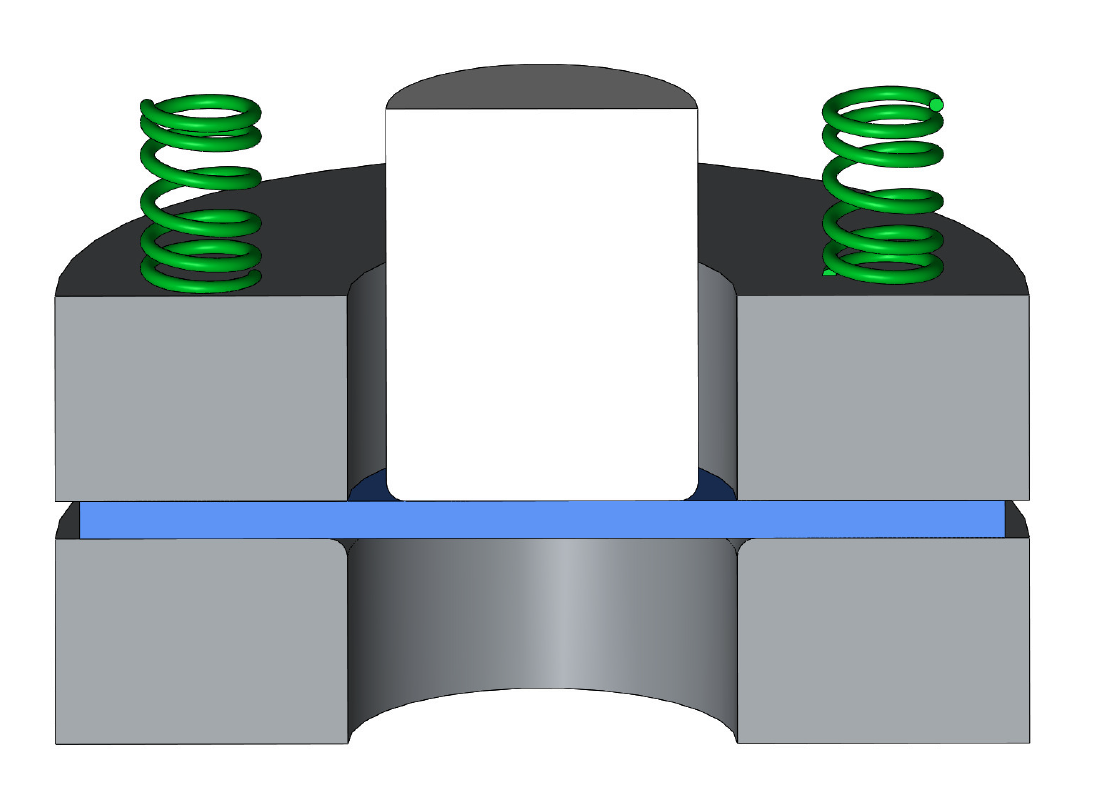

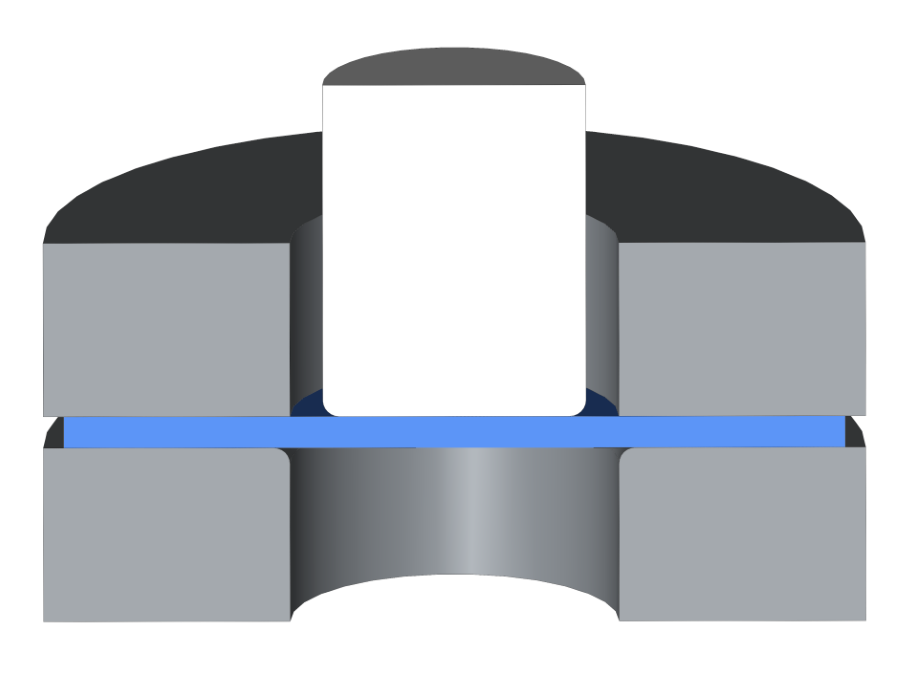

A simple deep draw tool is based on 3 different parts. The Die, Punch, and Blank holder. The die has the same dimensions as the outside of the desired product. The punch, which as an opposite shape, is used to press the material into the die. The blank holder is used to keep the material flat and prevent wrinkling.

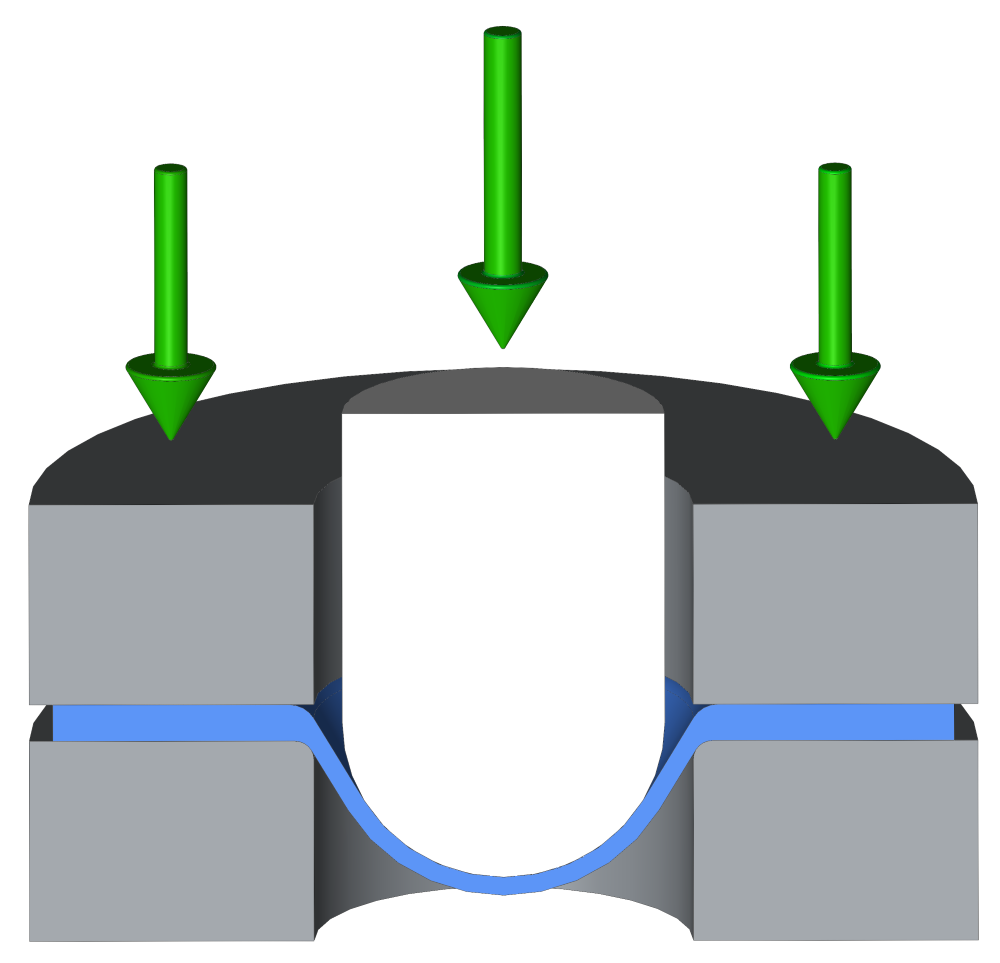

The starting material also called the blank is placed on the die and clammed by the blank holder with a predefined force. This force is enough to prevent wrinkling but still gives the material the possibility to flow inwards. The punch then presses the blank into the die, where at the end a product is formed.

Want to know how to design a deep drawn product? See this link

Drawing vs stretch forming

Many people mix-up deep drawing with stretch forming. However, there is a fundamental difference between both techniques.

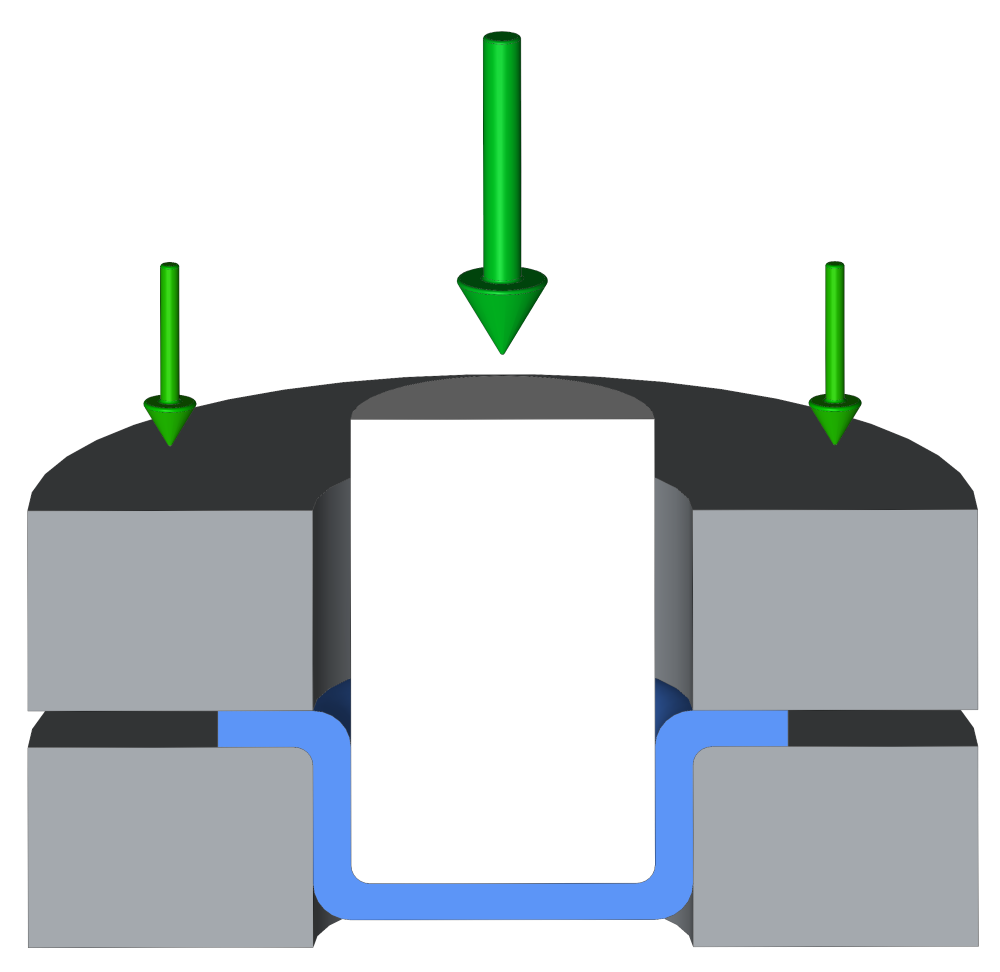

With stretching the blank is being clamped en pressed in the die with a punch. The material doesn’t flow into the die, but it stretches what makes the material thinner.

With deep drawing the material is also clamped. However, this is done with a predefined force, which gives the material the possibility to flow into the die. At the moment the material flows inwards, the blank diameter reduces which gives a compression perpendicular to the pulling direction. This stretch in the length and compression in the width equalizes each other. Therefore the material theoretically doesn’t change in thickness. This gives a three-dimensional end product with equal wall thickness.

Below both processes next to each other. Deep drawing left and stretching right.

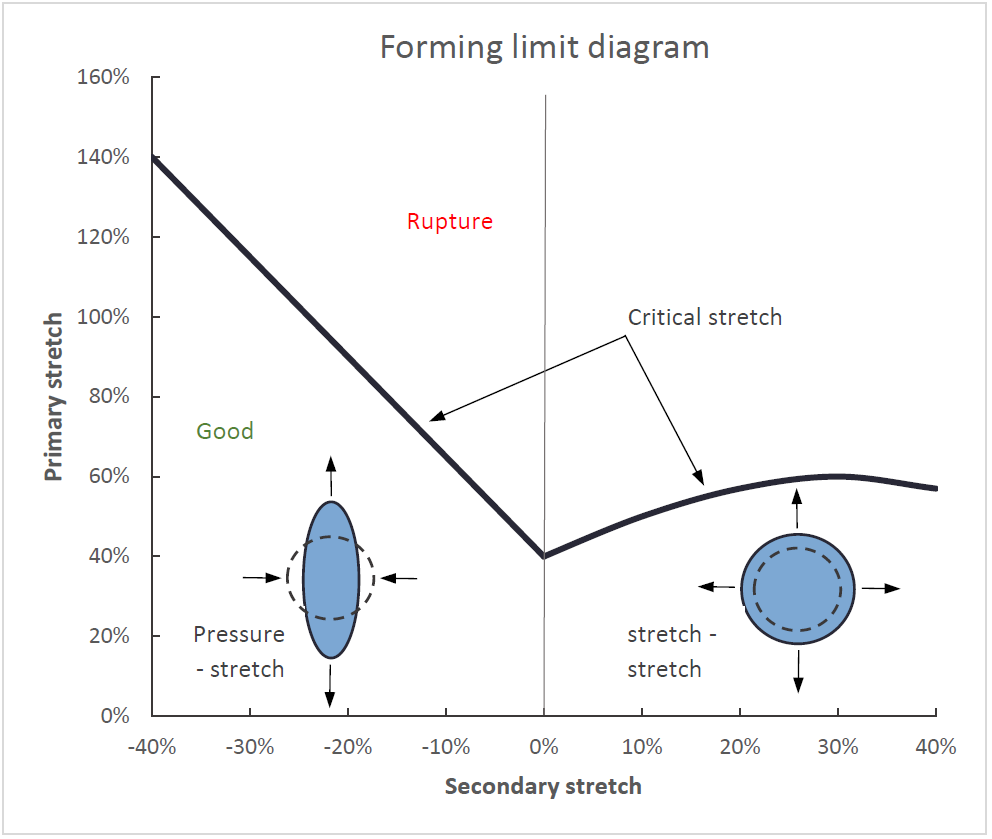

Forming limit diagram

When we look in more detail at the tension in the sheet, the forming limit diagram can give us a good insight into the differences between both techniques. The vertical axis shows the stretch created by a punch when the material is drawn inwards. The horizontal axis reflects the stretch in the perpendicular direction. At the left deep drawing and at the right stretching. When a circle is drawn onto the sheet. This circle will be an ellipse with the same thickness after deep drawing and a bigger circle with a reduced thickness after stretching.

See this link if you want to know more about the benefits of deep drawing compared to machining.

Do you want to know what deep drawing can do for your business? Please contact us!